YOUR PARTNER IN A BETTER WORLD

Vulcraft is ready to help make your business stand out by developing a sustainability plan for the steel in your next project. Our experts understand your company’s needs and can provide detailed information on embodied carbon content for your project proposals.

SUSTAINABILITY STARTS HERE

No matter where you are in the building process, we’re here to support your sustainability goals. Dive into detailed planning with EPDs, content letters, and Declare product label information, explore research and education, and understand your final environmental impact using our sustainability calculator.

A HISTORY OF DECARBONIZATION

Vulcraft sources all its steel requirements from Nucor’s circular steelmaking plants. Nucor is known industry-wide for successfully optimizing its carbon footprint for over 50 years. Nucor steel is produced with an average recycled content greater than 75 percent via electric arc furnace (EAF) technology, significantly reducing its carbon footprint to one third of the global extractive steelmaking average.

RECYCLED STEEL

Steel is unique in its ability to be repeatedly recycled and reused without loss of quality. Vulcraft manufactures steel products that are made from an average of 77.3 percent recycled content, with some products containing nearly 100 percent recycled content. The steel from a vehicle may have been recycled multiple times before becoming the Vulcraft steel deck that forms the building blocks of your stunning design.

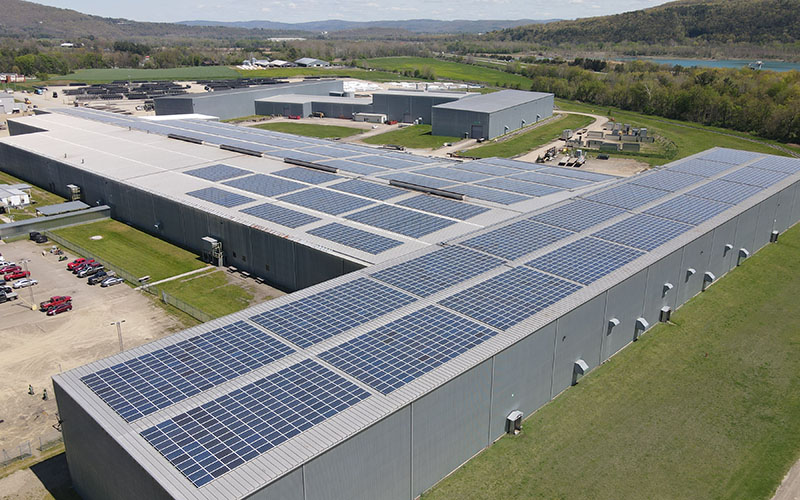

SOLAR ENERGY

Vulcraft is firmly committed to increasing our use of renewable energy, which is why you can find solar fields at several of our facilities. Vulcraft is doing what we can to be good stewards in the communities where we work and live by harnessing natural energy and lowering our carbon footprint.

RESOURCES

SUSTAINABILITY DOCUMENTS

ENVIRONMENTAL PRODUCT DECLARATIONS

Environmental Product Declarations (EPDs) are independently verified, ISO-compliant documents that transparently report the environmental impacts of construction products. They are used by architects, engineers, and builders to compare materials in order to meet sustainability and LEED goals.

FABRICATED OPEN-WEB STEEL JOISTS AND JOIST GIRDERSThe EPD reports quantified environmental impact indicators, including Global Warming Potential (GWP), for fabricated open-web steel joists and joist girders manufactured at Vulcraft facilities in the United States.

FABRICATED STEEL ROOF AND FLOOR DECKThe EPD reports quantified environmental impact indicators, including Global Warming Potential (GWP), for fabricated steel roof and floor deck manufactured at Vulcraft facilities in the United States.

SUSTAINABILITY & COMPLIANCE RESOURCES

SUSTAINABLE STEEL SPECIFICATION GUIDENucor sustainable steel specifications can help you inform material procurement practices, creating a path to source steel with fewer carbon emissions

RECYCLED CONTENT LETTER MILL PRODUCTSVulcraft's Recycled Content Letter for Mill Products showcases Nucor's recycled steel averages, information essential for LEED certification and sustainable building projects.

RECYCLED CONTENT LETTER STEEL PRODUCTSVulcraft's Recycled Content Letter for Steel Products highlights steel joists and deck recycled content averages, supporting architects and builders in North America pursuing sustainable construction and LEED certification.

DECLARE LABEL – FABRICATED STEEL ROOF & FLOOR DECKNucor’s Fabricated Steel Roof and Floor Deck Declare Label offers transparency and can help comply with the Living Building Challenge certification.

DECLARE LABEL – FABRICATED OPEN-WEB STEEL JOISTS & JOIST GIRDERSNucor’s Fabricated Open-Web Steel Joists and Joist Girders Declare Label offers transparency and can help comply with the Living Building Challenge certification.

RESOURCES

ONLINE DESIGN TOOL:

SUSTAINABILITY CALCULATION TOOLThe Vulcraft Verco Sustainability Calculator is an essential tool for architects, engineers, and builders to efficiently assess and compare the Global Warming Potential of joists and decks in construction projects while aligning with sustainability standards.

Sustainability Calculator Video Tutorial

INDUSTRIAL RESEARCH:

KL&A SUMMARYThe KL&A North American Steel and Hybrid Steel-Mass Timber Structural Systems Report is a comprehensive, low-carbon comparison of conventional steel and hybrid steel-timber floor and roof systems for commercial and residential buildings, covering embodied carbon, costs, system depth, GWP, fire protection, and acoustic/vibration performance.

NORTH AMERICAN STEEL AND HYBRID STEEL AND MASS TIMBER STRUCTURAL SYSTEMSKL&A Engineers & Builders’ North American Steel and Hybrid Steel Mass Timber Structural Systems Report compares steel and hybrid mass timber systems, examining embodied carbon, costs, and structural depth for commercial and residential use.

NORTH AMERICAN HYBRID STEEL AND MASS TIMBER STRUCTURAL SYSTEM DESIGN CONSIDERATIONSKL&A Engineers & Builders’ Design and Construction Considerations Report expands on its North American Steel and Hybrid Steel Mass Timber Structural Systems Report, considering fire, acoustic, and vibration performance of the different floor assemblies.

MAGAZINE ARTICLES:

LIFE CYCLE OF STEEL JOISTSExplore The Untold Life Cycle of a Steel Joist, a look at open-web steel joists from production to end-of-life, covering manufacturing, environmental impact, decarbonization strategies, circular economy benefits, and real-world reuse cases for sustainable steel construction.

NAVIGATING SUSTAINABILITYModern Steel Construction’s Navigating Sustainability article explains life-cycle assessment (LCA), environmental product declarations (EPD), and whole-building life-cycle analysis (WBLCA) for steel structures, showing how cradle-to-gate/cradle-to-grave/cradle-to-cradle approaches measure embodied carbon and guide sustainable design and procurement choices.

FIND SUSTAINABILITY EXPERTS

If you are looking for sustainability experts, we can help!

Connect with a Vulcraft specialist to learn more about creating a customized sustainability plan for your next project.

Find the nearest expert: