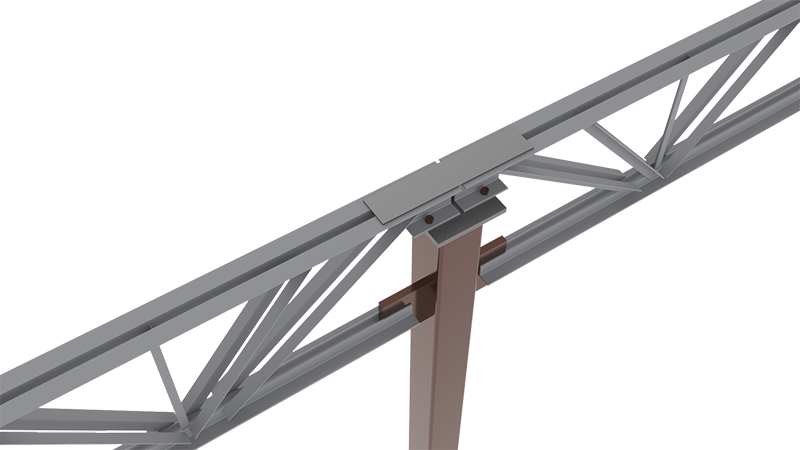

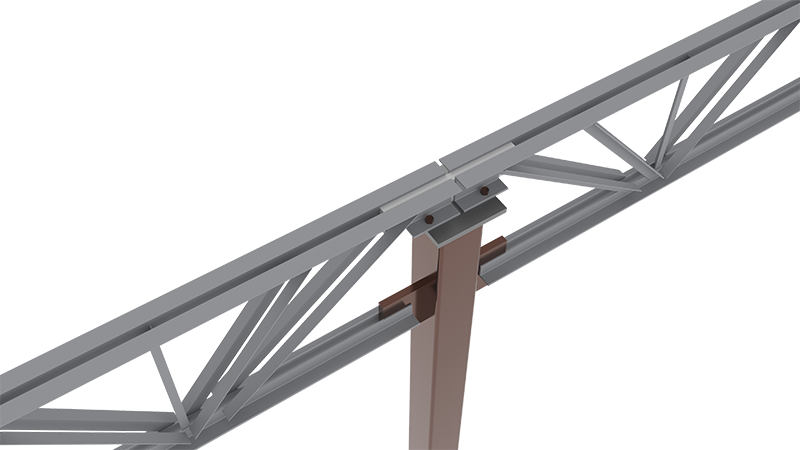

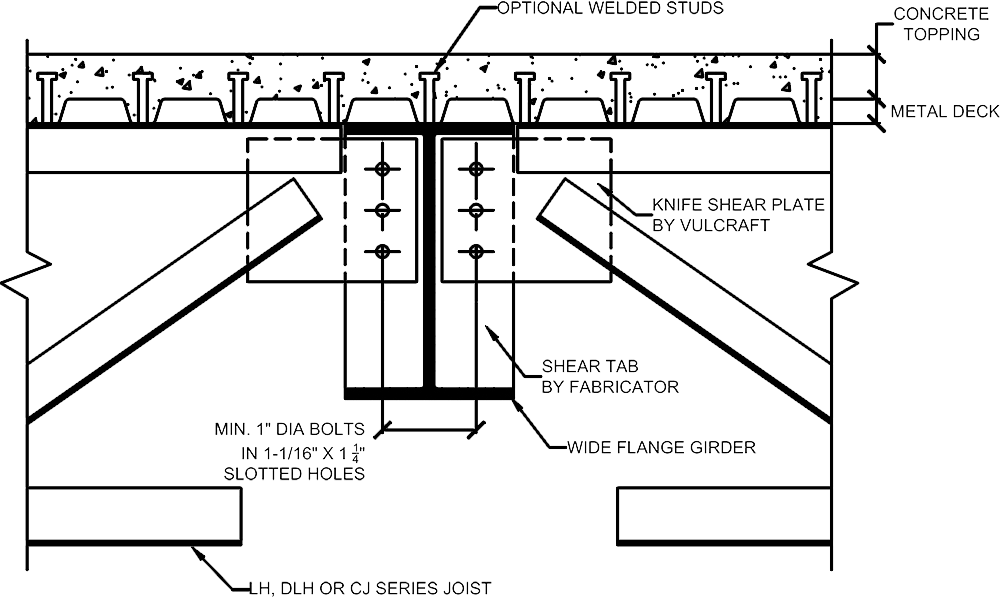

JOIST FLUSH FRAME CONNECTIONS

Vulcraft’s Flush Frame Connections are modernizing steel joist floor systems. Recent research shows that our Flush Frame Connections significantly mitigate floor vibration* making your building safer and more comfortable. Designed to reduce floor-to-floor heights, simplify MEP installation, and accelerate deck installation, Flush Frame Connections also combine the strength of a wide flange beam connection with the lightweight advantages of an open web joist.

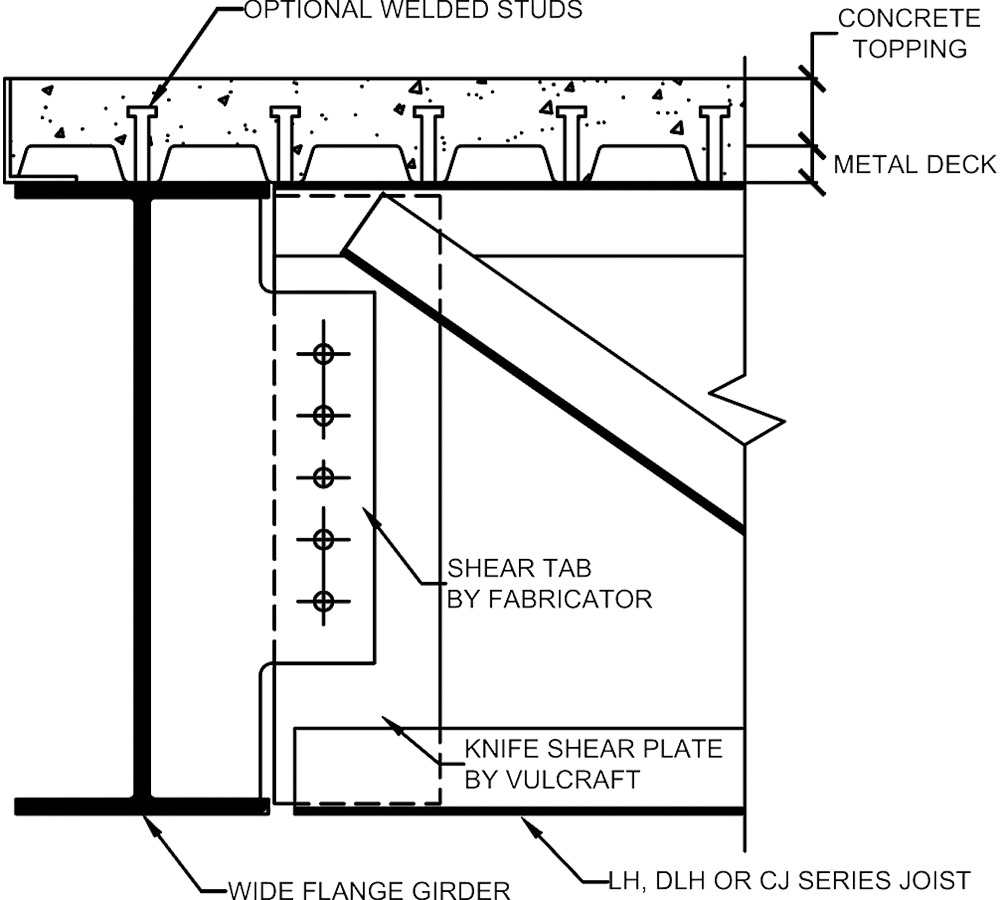

As the name implies, Vulcraft’s Flush Frame Connection places the joist’s top chord flush with the girder’s top flange, bolting the joist plate to a shear tab on the girder. These connections are another example of how Vulcraft’s steel joist floor systems provide more options and less vibration.

* As measured by finite element analysis and manual calculation methods.

DESIGN SPECIFICATIONS

- Enhanced floor vibration characteristics

- Faster erection

- Possible reduction in floor-to-floor height

- Simplified deck installation

- Girders can be designed deeper and/or composite

- Easier MEP installation

- Eliminates blocking between joists

FLUSH FRAME TYPES

VIERENDEEL OPENINGS

Vulcraft’s joists can be custom designed with rectangular Vierendeel openings to allow large heating, ventilation, and air conditioning (HVAC) ducts to pass through the open web system. Doing so reduces the required floor-to-floor height, as the MEP can run through the Vierendeel opening rather than beneath the joist bottom chord.

The Vierendeel opening should be located near the minimum vertical shear across the steel joist (typically near the joist mid-span for a uniformly loaded joist). Doing so reduces the combined vertical shear forces required to be carried by the joist top and bottom chords, resulting in the greatest joist weight savings. Vierendeel openings provide maximum flexibility with MEP layout – making them ideal for multi-story buildings.

DESIGN SPECIFICATIONS

- Opening locations and clear dimensions must be indicated on framing plans or in joist elevations

- Note that wider openings may result in larger top/bottom chord angle sizes, limiting vertical dimensions

- Partial span live loading will be checked by Vulcraft

- Any special loading conditions should be provided

AXIAL LOADS

If you’re building in an area that experiences high wind or seismic forces, Vulcraft’s custom-engineered steel joists can help. Incorporating joists in your lateral-resisting system is straightforward and cost-effective.

Our team of experts can help you navigate your structure’s challenges and manage complex load paths, even in the most demanding conditions.

The specifying professional should note the axial load on the drawings, whether it is due to wind or seismic forces, and whether ASD or LRFD design loads are to be used.

DESIGN SPECIFICATIONS

DEEPER SEATS WILL HAVE DECREASED CAPACITY.

OPEN WEB STEEL JOISTS

Joists are excellent for resisting the various wind or seismic lateral loads that a building may experience. These are often translated into axial loads, which are in the direction of the joist length. While these loads may accumulate or dissipate through the deck diaphragm, they often need to be transferred from the end of one joist into the adjacent one.

The seat of the joist has some capacity to resist axial loads. The load path would be through the joist-bearing seat into the shared girder member and into the next joist’s bearing seat. But this is not an ideal condition for larger loads.

When the axial loads exceed 26 kips / 200 kips, then additional transfer material is needed. In these types of scenarios, we recommend a tie plate (Detail A), angle (Detail B), or knife plate (Detail C).