Navigating Special Loading Requirements: Best Practices for Communicating Joist Specifications

In the world of construction, clarity is key. The Steel Joist Institute requires engineers to clearly communicate all loading information to joist manufacturers, and with good reason. Using a standard designation (e.g. 16K3) combined with an "SP" special loading designation is one option that requires extra care to specify properly. This article will explain best practices for clearly conveying loading requirements to joist manufacturers, especially when using a standard+SP designation.

VARIED SPECIFICATIONS FOR LOADING: IMPLICATIONS FOR JOIST DESIGN

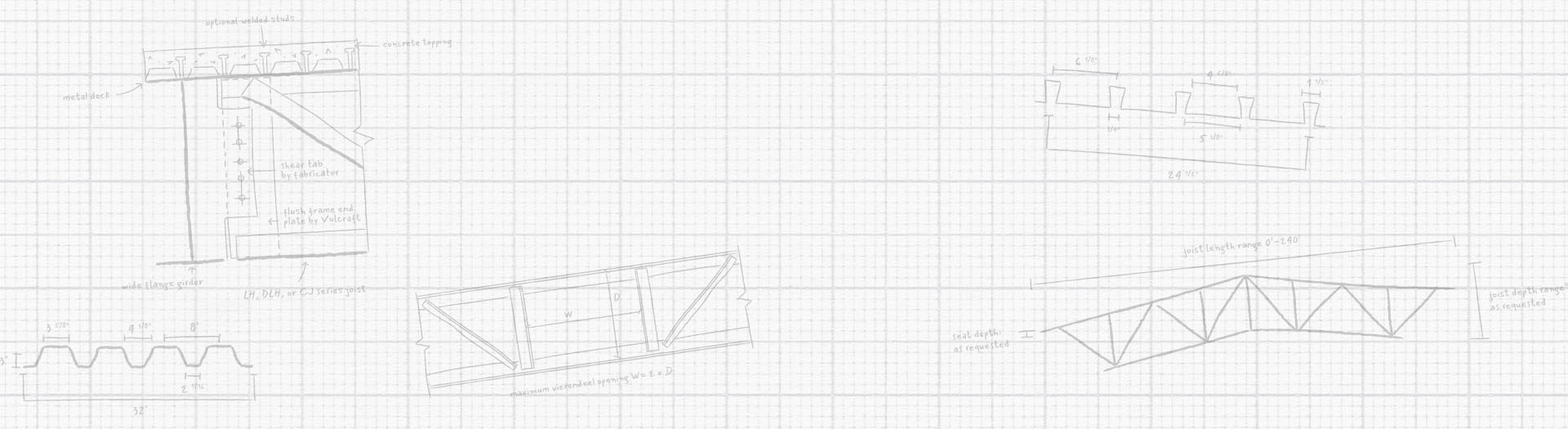

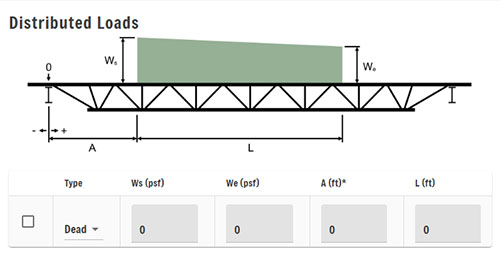

Loading can be specified in several ways, including standard designations that correspond to load tables (e.g. 16K3), total and live load magnitudes (e.g. 100 psf total load, 40 psf live load), or detailed load diagrams showing distributed loads, point loads, etc. Joist designs are custom for each project based on span, support conditions, loading, and other factors, so incomplete or ambiguous loading specifications can result in improper joist designs.

UNDERSTANDING STANDARD JOIST DESIGNATIONS AND LOAD TABLES

Standard joist designations, such as 16K3, correspond to tabulated uniform load capacities for a given joist configuration and span. They’re meant to be used as a convenient shortcut for engineers to quickly specify joists for simple uniform loading conditions. Load tables hinge on the total load magnitude, assuming a breakdown of dead, live, and collateral components. To ensure structural resilience, these designations often include extra capacity, but it’s most economical when actual loading closely matches the assumed breakdown in load tables. In addition, specifying joists isn't as straightforward as choosing a designation off the shelf; factors like span, support conditions, and other details affect the actual joist design and fabrication.

COMMON EXAMPLES OF A STANDARD+SP SPECIFICATION WITH INCOMPLETE INFORMATION

Items of incomplete information include:

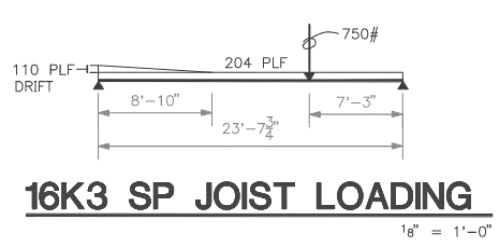

- Is the SP joist loading to be applied in addition to the 16K3 standard loading, as a replacement of the 16K3 loading, or is the joist designed for the worst-case scenario of either the 16K3 or the SP loading diagram provided?

- Joists are designed using the same ASCE 7 loading combinations as the specifying professional would use for determining any other structural element on the project. The diagram fails to properly identify the load types or components of the load as Dead Load, Live Load, Snow Load, etc. to allow for a proper and complete analysis for stress and deflection.

- The diagram lacks grid references to ensure proper orientation of the joist in plan location with respect to the requested loading.

ADDRESSING SPECIAL LOADING REQUIREMENTS WITH 'SP' DESIGNATIONS

Many projects have special loading requirements beyond what is covered by standard uniform load designations, such as large point loads, significant non-uniform/triangular loads, or special load combinations. The "SP" suffix added to a standard designation, e.g., 16K3SP, indicates special loading. The intent is for the engineer to provide additional loading details to augment the base standard loading. This could be a load diagram, a narrative description of additional point/axial loads, special deflection criteria, etc. However, problems arise when the special loading information is incomplete, unclear, or not provided at all. Joist designers will require additional clarification, typically coordinated through RFIs, before finalizing the joist calculations.

OTHER BEST PRACTICES FOR COMMUNICATING SPECIAL LOADS:

- Explicitly state all loading requirements beyond what is covered by the base standard designation. Are the loads to be applied in addition to the designation, as a replacement for the designation loading, or is the joist to be designed for the worst case of either the designation or the specified loading diagram?

- Provide load diagrams that clearly show the magnitude and location of all non-uniform and point loads with load types (DL, LL, SN, W, etc) clearly designated.

- Specify any axial loads, lateral loads, or special load combinations that need to be considered in addition to the gravity loads (for example, specifying an "add load" of 500 lbs that can be applied anywhere on the joist allows flexibility compared to a specific point load location)

- Note any deflection or moment of inertia requirements that differ from the specification standards

- Review joist submittals to verify all loading requirements have been captured correctly

- Work with the joist manufacturer to identify opportunities to simplify loading and improve efficiency within acceptable tolerance. This can be achieved by using the add load approach for miscellaneous point loads, consolidating similar loading conditions to reduce variations, and making conservative assumptions to reduce RFIs and design iterations.

Establishing a partnership with a trusted joist manufacturer like Vulcraft is highly recommended, as it further reduces miscommunication. Joist manufacturers rely on clear, complete loading information from engineers to design and fabricate joists efficiently, so an existing relationship between the two can be very beneficial. Using standard designations with special SP loading provides flexibility but introduces opportunities for miscommunication. Taking the time upfront to convey joist loading requirements clearly and completely saves time, cost, and headaches through the rest of the design, fabrication, and erection process.

About the author

Gerald McKenzie, SE (UT), PE (ME, DE, TN) is a Design Engineer in Vulcraft's Indiana division. He has 20 years of experience as a specifying engineer of record, with 13 years as part owner in a consulting engineering firm in the Salt Lake City area. He also has five years of project management experience for a commercial construction company.