Tackling Vibration Issues in Your Next Project

When you're knee-deep in the design phase of your next big project, it's important not to overlook potential vibration issues. These seemingly minor annoyances can turn into significant problems, from occupants’ discomfort to malfunctions in sensitive equipment. As structural engineers, our role in addressing these vibrations early on can make or break a project's success. In this article, we'll dive into the basics of vibration in buildings, discuss design strategies, and explore how partnering with experts like Vulcraft can help you keep these issues in check.

UNDERSTANDING THE BASICS OF VIBRATION IN BUILDINGS

Vibrations in buildings can originate from a variety of sources, including:

- Human Activity: Walking, running, and jumping can all cause noticeable vibrations, especially in residential and office buildings.

- Mechanical Equipment: HVAC systems, elevators, and other machinery are common culprits.

- Industrial Processes: Manufacturing equipment, heavy machinery, and assembly lines can generate significant vibrations.

- External Factors: Traffic, nearby construction, and even seismic activity contribute to vibration levels.

There are several factors that influence how vibrations travel through a building, such as:

- Building Materials: Steel, concrete, and wood each have unique properties that affect vibration.

- Structural Design: The layout, including floor spans, column spacing, and connections, plays a significant role.

- Damping Characteristics: Materials and finishes can help absorb and reduce vibrations.

If vibrations aren’t properly managed, they can lead to:

- Occupant Discomfort: This can range from mild annoyance to motion sickness.

- Reduced Productivity: Office spaces may see a drop in efficiency.

- Interference with Equipment: Laboratories, medical facilities, and manufacturing processes can suffer.

- Safety Concerns: In extreme cases, excessive vibrations can cause panic and potential safety risks.

DESIGNING STEEL STRUCTURES TO MINIMIZE VIBRATION

Steel structures are particularly prone to vibrations thanks to their material properties. Accurate analysis and design are critical for controlling these vibrations.

When designing steel structures, consider these important factors:

- Material Selection and Mass Distribution: Heavier materials and well-distributed mass help reduce vibrations.

- Structural Layouts and Spans: Optimizing these can significantly impact vibration levels.

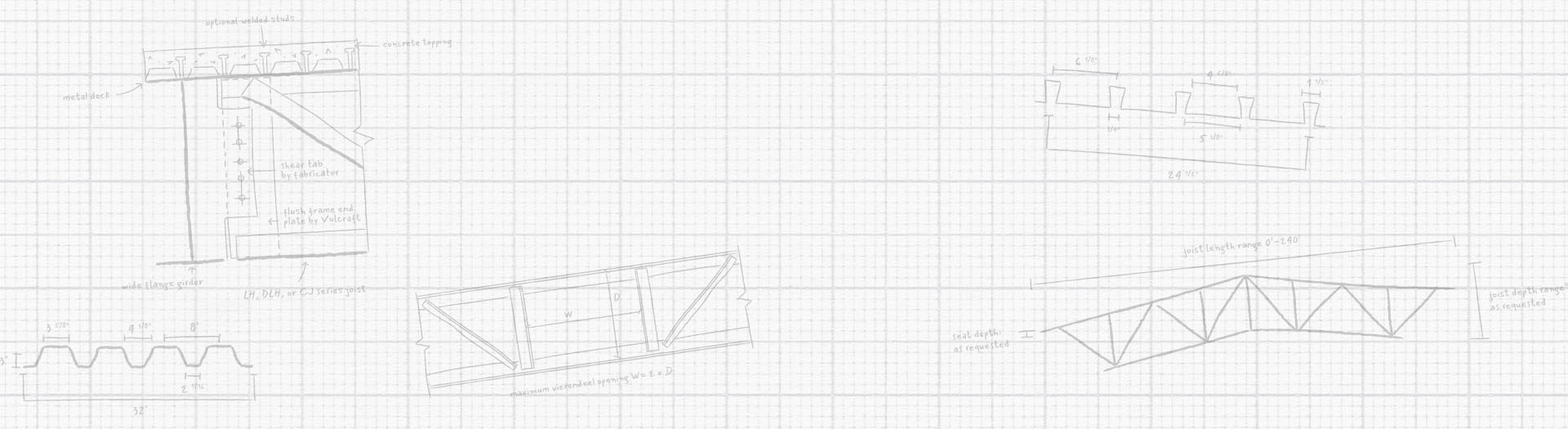

- Connection Types and Details: Flush-frame connections, for example, can lessen vibration transmission.

- Damping Strategies: Both passive (like viscoelastic materials) and active (such as tuned mass dampers) damping techniques are vital.

MITIGATION STRATEGIES FOR VIBRATION CONTROL

Some effective structural modifications for vibration control include:

- Increasing Mass and Stiffness: Heavier and stiffer joist systems exhibit less felt vibration.

- Optimizing Span Lengths and Column Spacing: Proper spacing can help distribute loads more evenly.

- Composite Construction Techniques: Using composite joists can enhance structural integrity.

Both passive and active damping techniques are essential:

- Passive Damping: Materials like viscoelastic substances and devices like tuned mass dampers can absorb vibrations.

- Active Damping Systems: Technologies such as active mass drivers and piezoelectric actuators actively counteract vibrations.

Even the building's interior can help mitigate vibrations in the following ways:

- Floor Finishes and Coverings: Carpets and other finishes can dampen vibrations.

- Partition Walls: These can absorb and minimize vibrations on floors both above and below them.

- Sensitive Equipment: Specially designed mounts and isolation systems can protect delicate equipment.

HELP TO ACHIEVE OPTIMAL RESULTS

Partnering with experts like those at Vulcraft early in your project can help address vibration concerns right from the start, leveraging their tools and knowledge to minimize costly redesigns and delays. We offer an online vibration tool specifically for joist design, which includes items such Vulcraft’s flush frame connections for accurate modelling. By inputting key parameters, you can interpret the results and iterate their designs for optimal performance in your project.

We also provide continuous support, from initial consultations and problem definition to modeling, analysis, recommendations, and assistance during construction and commissioning.

Addressing vibration issues is crucial for ensuring occupant comfort and building functionality. Structural engineers play a key role in this process, and with the right tools and support, these challenges can be managed effectively. Tackle vibrations head-on and consider early collaboration with experts to keep your designs running smoothly.

About the author

Dave Goodridge, P.E. has worked in the structural steel industry for 15 years, with experience as a forensic engineer and project engineer. He earned a Bachelor of Science in Civil Engineering from SUNY. He is currently a design engineer with the Nucor - Vulcraft Group.

RELATED RESOURCES

More on Mitigating Vibration with Flush Frame Connections

This article from Structural Connections shows how the frequency and effective mass of the floor bay can be changed dramatically when switching from traditional bearing seats to flush frame connections developed by Vulcraft.

Vulcraft Vibration Research Case Study

As part of the continual research and development efforts for Vulcraft joist floor systems, a vibration research program was performed for the Fifth and Sixth Floors of a new building in Boston, Massachusetts. The purpose was to investigate the vibration performance of a composite joist floor system with flush framed connections.

Vulcraft’s Joist Flush Frame Connections

Designed to reduce floor-to-floor heights, simplify MEP installation, and accelerate deck installation, Flush Frame Connections also combine the strength of a wide flange beam connection with the lightweight advantages of an open web joist.