Maximizing Installation Efficiency in Structural Steel Floor Systems

WHY INSTALLATION EFFICIENCY MATTERS

Time is money, especially in construction. The faster a floor system goes in, the more potential savings there is to the project schedule and labor costs. The best way to accomplish this is with an optimized structural design and as few pieces to handle as possible. Vulcraft offers several best practices, products, and design aids to help accomplish this. Let’s jump in to discuss 1) reducing the number of deck and joist pieces being handled in the field, 2) minimizing (or avoiding) shoring of deck-slabs, and 3) efficient sidelap connection design.

FEWER PIECES = FASTER INSTALLATION

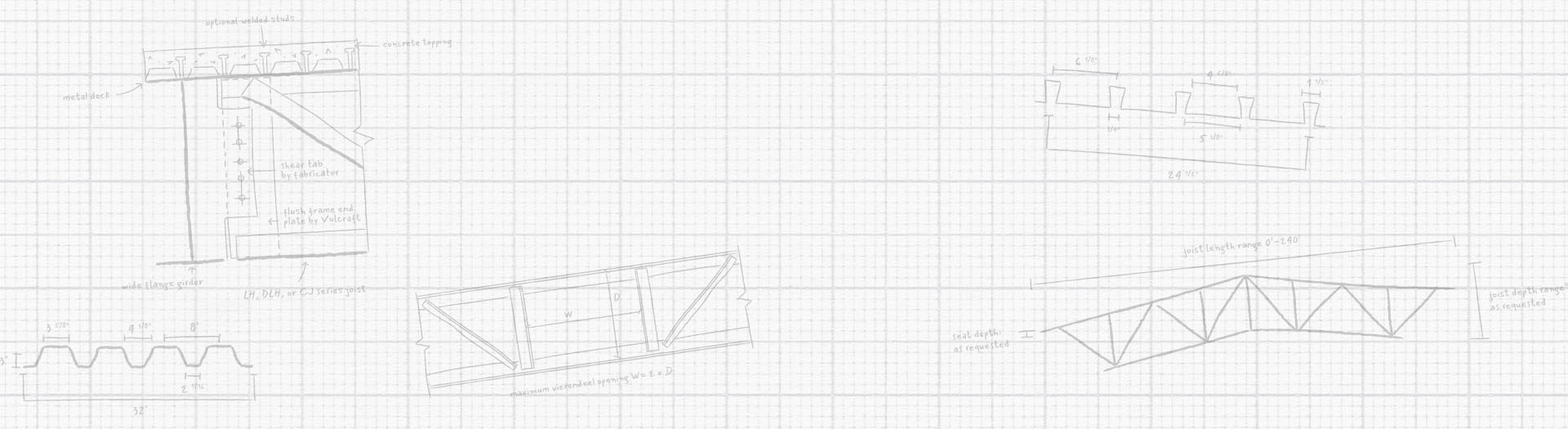

The fewer pieces to install, the quicker the job gets done. The first key concept is maximizing the support spacing that your desired floor deck-slab can span. For example, if your fire rating calls for a 2VLI composite deck + 4 ½” topping of normal weight concrete, that deck-slab’s structural capacity is essentially locked in. It has a “floor,” if you will, and 20ga deck in this case corresponds to an 8’-6” maximum unshored two span condition. So why not space your supports as close to 8’-6” as possible? Closer spacing just adds pieces without saving any weight in the deck-slab. And the joist system itself stays roughly the same weight, whether it’s a small quantity of joists each carrying a large load or the inverse. The trick is to be aware of your maximum allowable deck spans and maximize joist spacing to fit within that bound.

However, there is a tradeoff. As the spacing between joists increases, the structure may be more susceptible to higher vibration. You can check vibration performance for typical human walking activity with our Vibration Analysis online tool. More advanced analysis may be required for other vibration checks.

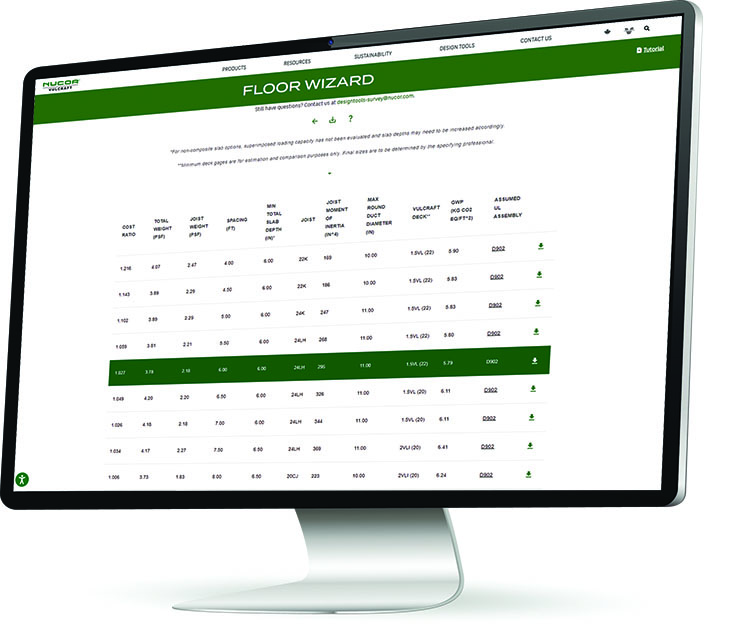

Juggling all those variables to find the optimal sweet spot is overwhelming. That’s why Vulcraft offers two key resources to help. First is the Floor Wizard online tool. The Floor Wizard takes the starting parameters of your scenario and automates the analysis described to offer the most economical combination of joist depth, spacing, deck type, and concrete slab; all while keeping within clear height requirements and meeting fire protection needs. The other is the recently released Floor Joist & Deck Systems Specification Guide, which features additional commentary and guidance on economical designs.

Wider deck sheets also make a big difference. For example, consider a scenario between two types of deck with 24-inch vs. 32-inch sheet coverage (assuming all other attributes are equal). The wider sheets increase coverage by 25%, resulting in fewer pieces to handle and fewer sidelaps to connect while covering the same square footage. Vulcraft began offering this very option for 3” deep N roof deck in the mid-2010’s to deliver a more convenient, higher-value option to the market. Similarly, our recent re-engineered 2” Dovetail profiles are now supplied in 30-inch wide sheets versus the previous 24-inch coverage.

REDUCE OR ELIMINATE SHORING

“Shoring” refers to temporary supports for the deck while it is carrying wet concrete. It is generally not desirable due to adding time to the erection process and creating physical obstacles for other trades to maneuver around. Ensuring that a deck-slab’s support spacing does not exceed its maximum unshored span can eliminate the need for temporary supports, keeping the project moving. Vulcraft’s Unshored Construction Span online tool can help by quickly generating custom maximum allowable span tables for your unique conditions.

SIDELAP DESIGN: SMALL CONNECTION, BIG IMPACT

The deck sidelap connection greatly impacts installation speed and diaphragm strength. Similar to the other issues described in this article, how do you properly optimize between a few strong connections vs. lots of weaker ones? Here’s a quick rundown:

- Welding – Strong, but slow & expensive, and requires dry weather and certified labor

- Screws – Fast and budget-friendly, but lacking in strength for high-shear applications

- Buttonpunching – Negligible shear strength. Can be used to hold sheets together

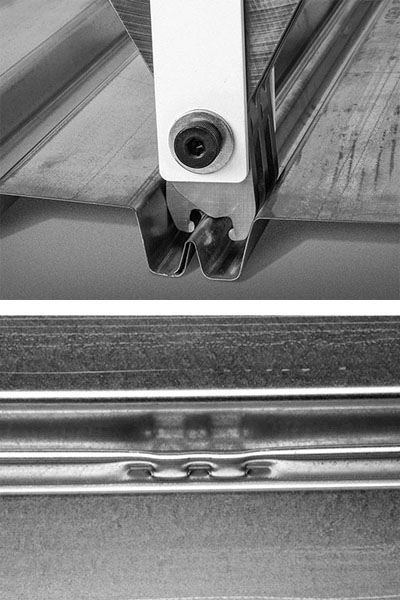

- PunchLok® – The sweet spot: strong, fast, and cost-effective

PunchLok® sidelap connections are only available with compatible Vulcraft or Verco deck profiles, identified with a “PL” modifier. For example, regular 1.5B deck has a lapped sidelap suitable for screws, while the 1.5PLB deck has an interlocking sidelap designed for a PunchLok® connection.

Not all deck types are compatible with all fastening methods. Choosing the right deck for the right method is vital for balancing design and speed of erection. Vulcraft and Verco are here to help alleviate the stress of selecting the right fastening method and deck type. Check out the Vulcraft Bare Deck Diaphragm online tool to start calculating the differences.

TAKEAWAYS FOR A SMOOTHER PROJECT

- Smart design upfront prevents major headaches later

- Fewer components mean faster, simpler installation

- Minimizing shoring keeps things moving

- Optimize joist spacing and deck selection early

- PunchLok® sidelaps offer the best balance of speed and strength

LET’S MAKE YOUR PROJECT MORE EFFICIENT

Every project is under pressure to save time and labor costs. Vulcraft’s design tools and products are built to help you do just that. Connect with your local Vulcraft rep to find the most efficient system for your next project.

About the author

Alex Brown is a Product Champion with Vulcraft/Verco's Innovation Services Group, where he researches, develops, and implements exciting new steel joist & deck solutions across North America. He has twelve years experience with Vulcraft, split between his current role and as Sales Engineer for Vulcraft's Chicago territory. Alex is a licensed Professional Engineer (Indiana) and a certified Construction Document Technologist through the Construction Specification Institute.