Future-Proof Your Space: Embrace Flexible Hanging Solutions for Lasting Adaptability

In a rapidly changing world, buildings must be as adaptable as the people and businesses that occupy them. This is where future-proofing comes in. Ensuring your building can handle evolving technologies, tenant needs, repurposing spaces, and unforeseen challenges requires a forward-thinking approach. Nowhere is this adaptability more critical than in Mechanical, Electrical, Plumbing (MEP) systems, medical equipment and other technology. Flexible hanging solutions play a pivotal role in this adaptability, enabling the installation of new systems, the relocation of existing ones, and the removal of outdated components.

WHY DOES FLEXIBILITY IN MEP SYSTEMS MATTER?

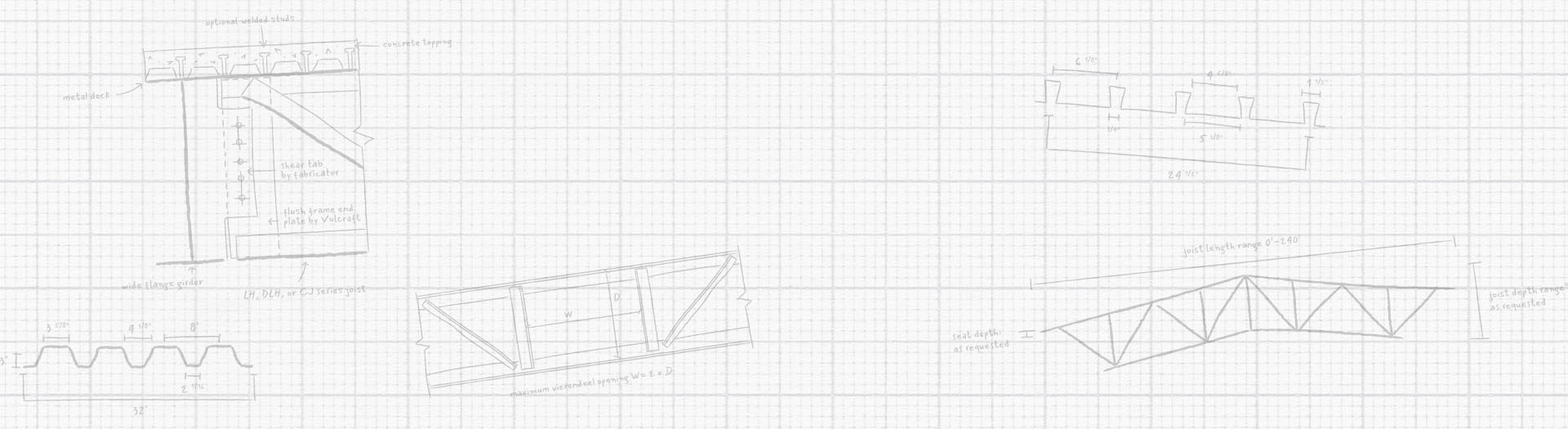

Flexibility in MEP Systems matters for sectors that simply can’t afford disruption. In certain building sectors, such as healthcare or data centers, there are strong incentives to always stay operational. That can be difficult long-term as technology advances or building use changes, necessitating renovation or reconfiguring spaces to accommodate new equipment. At Nucor Vulcraft & Verco, we recognize these realities and have developed hanging solutions that integrate seamlessly with our metal deck systems, allowing fast installation and relocation without structural modifications. This minimizes disruption, supports phased renovations, and helps maintain constant uptime in active facilities.

CURRENT CHALLENGES IN ADAPTING MEP SYSTEMS

Updating MEP systems isn’t always straightforward. Here are the main hurdles:

- Technological Change: Buildings like data centers and hospitals face constant upgrades. For example, data center hyperscalers aim for near 100% uptime, making traditional structural modification methods impractical.

- Physical Constraints: Drilling into concrete slabs creates silica dust, noise, vibration, and other disruptions.

- Cost and Time Factors: Traditional systems, such as wedge nuts and Blue Bangers involve multi-piece assemblies that slow installation and require more labor. These methods can be inefficient and more costly, especially over the long term.

INNOVATIVE HANGING SOLUTIONS FOR MEP FLEXIBILITY

Modern hanging systems are designed to simplify installation and boost flexibility:

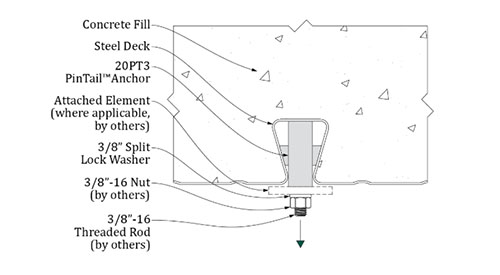

- Pintail Anchors: These single-piece solutions can support both hanging and lateral loads. Simply push the Pintail Anchor up, spin it, drop it into place, and tighten the nut. They are ideal for fast-paced projects and are exclusively designed for use with Vulcraft’s newly re-engineered Dovetail Decks. Pintail Anchors not only simplify installation but also allow for easy addition, relocation, or removal of hanging components.

-

Badger Hangers: These hangers are compatible with Verco W2 and W3 decking systems, offering moderate capacity for regional applications. Like the Pintail, Badger Hangers enable straightforward addition, movement, and removal of MEP components, providing flexibility where it is needed most. Additionally, these hangers require no drilling, making installation quick and hassle-free.

THE BENEFITS OF FLEXIBLE HANGING SYSTEMS

Innovative hanging solutions aren’t just convenient; they deliver measurable advantages:

- Ease of Installation: Pintail Anchors enable one-handed installation, maintaining three points of contact on a ladder for safety.

- Safety and Comfort: No drilling means no silica dust or disruptive noise, ensuring worker safety and tenant comfort.

- Adaptability: These systems can be easily added, relocated, or removed, crucial for spaces with changing needs, such as medical offices.

- Seismic Standards Compliance: Pintail Anchors and Badger claw hangers both offer lateral capacity, making them a viable option for seismic bracing and ensuring long-term stability.

LOOKING AHEAD: THE FUTURE OF MEP FLEXIBILITY

New developments and products - such new floor deck profiles, new hanging options, and new bracing capabilities via deck - are shaping the future of installing and renovating MEP systems. Ongoing research and case studies will continue to quantify the long-term savings and scalability of these innovative solutions.

Incorporating flexible hanging solutions for MEP design isn’t just about staying current; it’s about staying ahead. By reducing costs, improving safety, and ensuring adaptability, these innovations are the key to future-proofing your building.

As an engineer, the time to act is now. Choose solutions that meet today’s needs and anticipate tomorrow’s demands. If you’re looking at data centers, consider the wide range of Nucor’s offerings. For assistance with your next project, contact your local Vulcraft expert today.

About the author

Alex Brown is a Product Champion with Vulcraft/Verco's Innovation Services Group, where he researches, develops, and implements exciting new steel joist & deck solutions across North America. He has twelve years experience with Vulcraft, split between his current role and as Sales Engineer for Vulcraft's Chicago territory. Alex is a licensed Professional Engineer (Indiana) and a certified Construction Document Technologist through the Construction Specification Institute.