Clear-Span Structures: Unlocking Column-Free Design for Greater Versatility

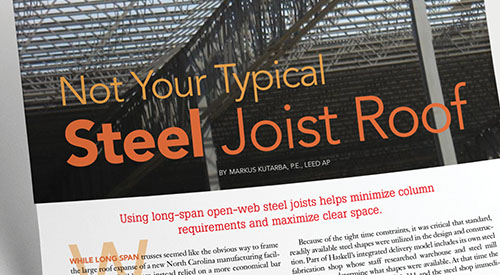

In modern architecture, the demand for wide, open spaces is higher than ever. From sports arenas and theaters to industrial plants and warehouses, column-free structures are the go-to solution for flexibility, aesthetics, and functionality. These spaces not only look impressive but also adapt to a variety of uses over time.

As a structural engineer, you play a crucial role in optimizing these designs. But achieving the right balance between feasibility and cost can be tricky.

STRUCTURAL SYSTEMS AND THEIR SPAN CAPABILITIES

Designing for long spans requires selecting the right structural system. Here’s a quick breakdown:

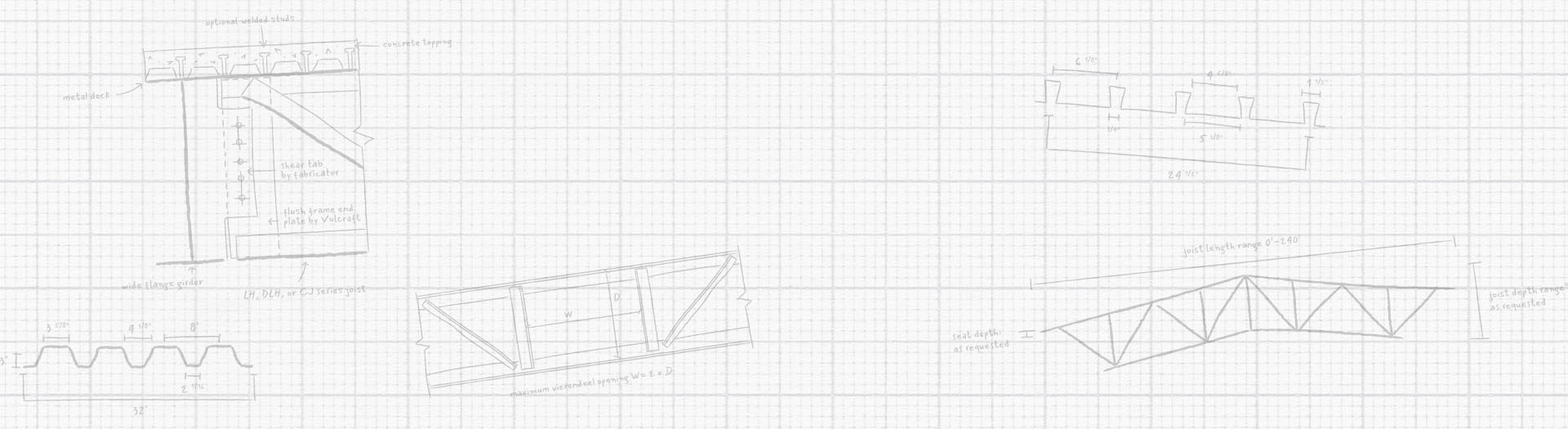

- Steel Joists and Girders: Known for their strength-to-weight ratio, steel is ideal for medium-to-long spans. A common rule of thumb is that one inch of depth is good for two feet of span, so a 48-foot span would need a minimum depth of 24 inches.

- Concrete Systems: Post-tensioned slabs can handle long spans but come at a higher cost and weight.

- Wood Systems: Limited by material strength, these are typically used for lighter-duty applications.

- Hybrid Systems: Combining materials, like steel frames with concrete or wood decks, optimizes performance and cost.

Steel systems often hit the sweet spot for spanning 50–200 feet. Their lightweight nature reduces foundation requirements, making them an economical choice. In addition, joists are typically lighter than equivalent wide flange beams due to their truss design, which consists primarily of open space.

COST-BENEFIT ANALYSIS OF INCREASED SPANS

While longer spans are functional and visually appealing, they come with a price tag. Material costs rise with the demand for greater strength and stiffness, and longer spans require specialized fabrication and installation. Transportation of oversized components can be challenging. When joists are too long to ship as a single piece, they may need to be delivered in sections and spliced together on-site.

However, the benefits of column-free spaces often outweigh the upfront costs. Open designs increase functionality, enhance property value, and make future tenant improvements more manageable.

FOUNDATION DESIGN IMPACTS

Larger spans mean fewer—albeit heavier— columns and foundations. Steel structures shine here with their high strength-to-weight ratio, which helps balance these concentrated loads economically. This approach involves allocating slightly more to the steel budget while reducing costs in the foundation budget.

DESIGN CONSIDERATIONS FOR ENGINEERS

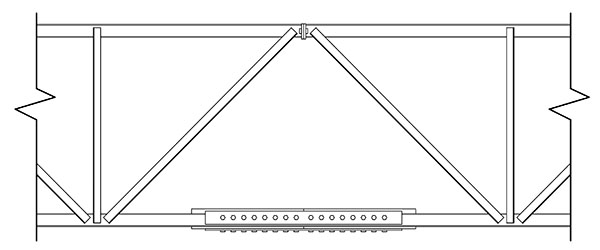

Large clear spans are possible for floors too. Joists have proven very economical in recent years for achieving 50+ ft spans in multistory warehouse and office building applications. Controlling vibration is critical for human occupancy of a floor and the joist industry has a solution in flush frame end connections. Flush frames provide a much stiffer connection to the girder/wall compared to a traditional joist seat, greatly reducing vibration in the final floor. Check out our Vibration Analysis online tool for more information. These bolted connections can also be fabricated as slip critical in compliance with AISC if required. Part of those requirements involve a lack of paint at the bolt locations, resulting in the unique looks of the joist pictured to the right.

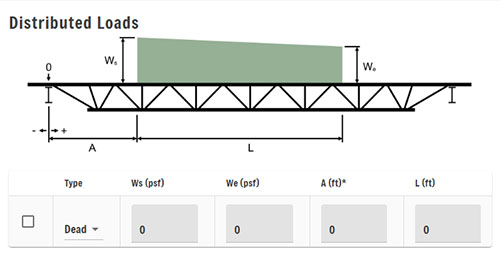

For any long span, considering the joist camber is essential. Upward camber helps offset expected downward deflection under the final gravity loading. Per the Steel Joist Institute, joists designed non-compositely (used overwhelmingly in roof structures) receive camber according to their span. Longer spans translates to more camber. This can cause field issues though if adjacent joists are significantly different spans or if the joist is close to a wall with a deck bearing angle. Luckily, joist camber is set during the production process and can easily be customized to whatever the project requires. We just need guidance from the specifying Engineer of Record on what to figure.

CHALLENGES AND SOLUTIONS

Clear-span designs don’t come without challenges. Coordination with mechanical, electrical, and plumbing (MEP) systems is crucial to avoid conflicts like ductwork interfering with bridging. Additionally, code compliance for deflection, vibration, and fire safety are critical as well.

Resiliency is key when considering upfront investments to safeguard against future uncertainties. By prioritizing short-term investments, you’re not only addressing immediate needs but also enhancing long-term adaptability. The core question becomes one of value: does this initial investment provide sufficient protection and flexibility to offset potential, unpredictable future costs?

WRAPPING UP

Clear-span structures offer unparalleled flexibility and value, making them a cornerstone of modern commercial design. By leveraging efficient systems like steel joists, you can create spaces that meet today’s needs while remaining adaptable for the future.

Emerging technologies and materials will only expand what’s possible in the years ahead. Structural engineers, the opportunity to push the boundaries of design has never been more exciting.

About the author

Alex Brown is a Product Champion with Vulcraft/Verco's Innovation Services Group, where he researches, develops, and implements exciting new steel joist & deck solutions across North America. He has twelve years experience with Vulcraft, split between his current role and as Sales Engineer for Vulcraft's Chicago territory. Alex is a licensed Professional Engineer (Indiana) and a certified Construction Document Technologist through the Construction Specification Institute.